in experience.

Our experienced team ensure the building continues to operate in accordance with its design.

workmanship at

competitve pricing."

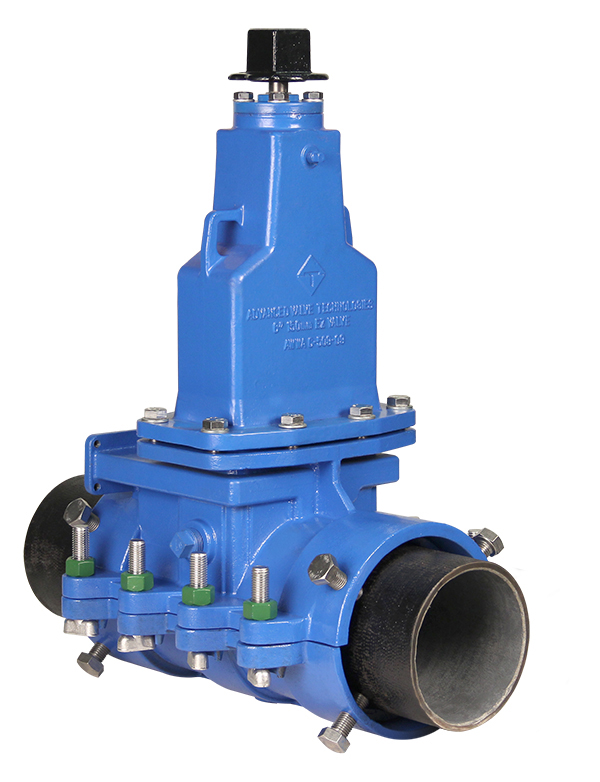

The EZ™ insertion valve system was developed to provide important performance and installation benefits to professionals working under difficult conditions and with critical needs, worldwide.

Both the final EZ™ assembly and the installation equipment kit have been developed to be lighter and more compact than alternative methods. The result: quick and sure installations in record times. It’s faster and easier, with fewer steps than older methods such as shutdowns and line stops.

The ductile iron castings, corrosion resistant coatings, and stainless steel fasteners incorporated in the EZ™ system have been carefully chosen and tested to deliver reliable and trouble-free service. EZ™ materials meet AWWA C-509-09/C-515 standards.

EZ™ components are manufactured and matched to deliver repeatable and dependable service. A complete insertion valve assembly can be created to meet your non-standard application or non-typical pipe material. Consult AVT for special projects.

An EZ™ assembly maintains pipe integrity while providing an easy-to-install, easy-to-use and easy-to-adapt solution. The full encirclement ductile iron casting design, narrow access resilient wedge valve, integral isolation valve and removable bonnet deliver field-elective operating options.

The “Take It or Leave It”SM valve bonnet feature provides the flexibility to either insert a permanent, high quality valve or temporarily use EZ™ for an economical and single excavation line stop.

EZ installs under pressure and in one excavation eliminating expensive multiple excavations. Faster installation times save man-hours while avoiding residential and business disruption to your system.

In comparison to traditional line stop equipment, EZ’s low-profile design usually permits plating over to keep traffic moving instead of requiring alternative routing and the attendant costs.